ALL STATES & TERRITORIES

Shank options enhance the versatility and flexibility of a plough and allow for more efficient and effective soil management and preparation, which can lead to improved soil health, increased crop yields, and reduced environmental impact.

Shank options are additional accessories that can be fitted to a plough’s standard shank or shank assembly to achieve different soil management outcomes. Whilst blades and shinguards can sometimes be classified as shank options as there are multiple styles available, they are generally categorised separately from shank options as they are necessary components of completed tyne assemblies.

Shank options enhance the versatility and flexibility of a plough and allow for more efficient and effective soil management and preparation, which can lead to improved soil health, increased crop yields, and reduced environmental impact.

Different types of shank options can be used for different purposes, such as primary or secondary tillage, weed control, and incorporation of organic matter.

Deep rippers are used to breakup deep compacted soil. Adding shank options to a deep ripper can be a cost-effective way to improve the efficiency and effectiveness of soil management operations, leading to better crop growth and yields, and promoting more sustainable agricultural practices. They enable single-pass tillage, which reduces input costs such as labour, fuel and time and minimises the effects of compaction from heavy machinery.

By having a range of shank options, farmers and contractors can tailor their deep-ripping operations to the specific needs of their fields and crops, optimizing soil health and crop yields while minimizing the use of synthetic inputs like fertilizers and herbicides.

There are many types of shank options available. Each one is designed to achieve different and specific soil outcomes. The most widely used are::

Coulters are mounted in front of the shank assembly of the deep ripper plough to help with cutting and slicing through tough soil, sod or plant residues before they are overturned by the shank. By cutting into the soil, coulters help to reduce soil resistance, making it easier for the shank to turn the soil over. The cleaner furrow created helps reduce soil disturbance, improves seedbed preparation, and can enhance overall deep ripping performance.

Coulters mount in front of the shank assembly and generally installed on smaller ploughs such as the AP11 Agrowplow.

Additionally, coulters help prevent clogging (trash buildup on the shank) by breaking up and clearing away debris in front of the shank for easier ripping in high-trash conditions. Whilst coulters can be installed on any size plough, they are generally recommended for smaller working-width ploughs only, such as the Agrowplow AP11 and AP31 deep rippers.

Mulch blades can be added to a shank to help cut weeds at the root level and incorporate plant residues such as crop stalks, stubble, and other organic matter into the soil during ploughing. This helps to increase soil organic matter, improve soil structure, and enhance soil fertility with minimal soil disturbance.

Mulch blades extend sideways behind a shank to cut weeds and stalks.

Mulch blades increase the ability of the deep ripper plough to cut through weeds and stubble and can help to reduce soil erosion and conserve soil moisture by creating a protective cover of organic matter on the soil surface. This can help improve soil health, reduce weed growth, and provide a better-growing environment for crops.

Additionally, installing mulch blades on a deep ripper can help to reduce the number of herbicides needed for weed control by creating a natural barrier that prevents weed growth. This can help reduce costs and promote more sustainable agricultural practices.

A furrower is a component that is bolted to the shank to create furrows (trenches) and hills (ridges) in the soil for raised bed cropping.

Furrowers are used in raised bed cropping.

Furrowers can be used to create trenches for planting crops such as potatoes, onions, and garlic. They can also be used for irrigation purposes by creating channels for water to flow through. Furrowing helps with soil drainage and erosion control by directing water away from the crops and preventing soil from being washed away.

Adding furrowers to your plough can also aid in weed control by creating trenches that help to bury weed seeds, preventing them from germinating.

Because of the increased drag of the implement, furrowers add approximately 10-25 hp to the drawbar requirement of the tractor for each shank installed on the deep ripper. It is important to note that the use of furrowers is not always necessary and may depend on the specific needs of the farmer or crop.

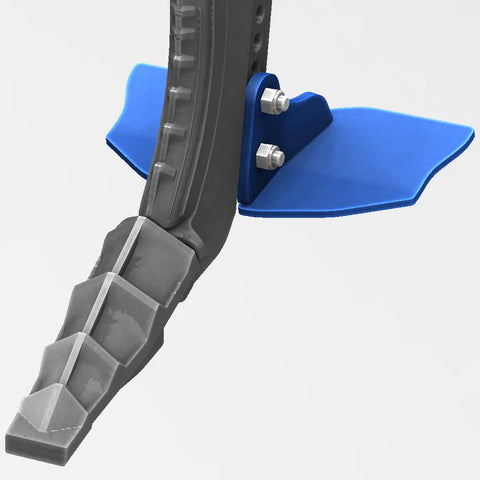

Inclusion plates are large metal plates that can be mounted to the rear of a shank to help manage surface residues, such as crop stubble or organic matter, during deep ripping.

Agrowplow Inclusion plates are compatible with any plough or shank that has 22mm hole spacings.

Inclusion plates open 'slots' below the surface of the soil behind deep ripping tynes to help direct the loosened topsoil into the furrow. This allows surface-applied ameliorants to be mixed into the subsurface soil layer.

Inclusion plates can be used to push surface residues down into the furrow created by the shank, burying them deeper into the soil. This can help prevent the residues from interfering with planting operations or nutrient uptake by the crop. The inclusion plates can also help to prevent residue from accumulating on the soil surface, reducing erosion and protecting the soil from temperature extremes.

Research has shown that attaching inclusion plates to the rear of deep ripper shanks, could deliver increased crop yields from deep sandy soils.

Agrowplow Inclusion plates are available in a range of sizes for shallow and deep top-soil slotting and can bolt onto any shank that has 22mm hole spacings. The protection plates that help keep the assembly from wear can be easily replaced, saving costs in material and time. They are built from a highly wear-resistant material and available in either shallow or deep variants.

Fertiliser tubes can be attached to a shank to deposit fertiliser from a seeding machine directly into the soil as the plough cuts through the soil. They allow the delivery of granular fertiliser directly behind the shank to adjust soil pH prior to sowing. This helps to ensure that the fertiliser is placed at the right depth and location to promote optimal plant growth and yields.

Agrowplow's 38mm fertiliser tube options come as dual with depth stop, single with depth stop, or single varieties.

By placing the fertiliser in the soil during deep ripping, it can be more efficiently utilised by the crops, reducing the amount of fertiliser needed overall. Additionally, placing fertiliser in the soil during ploughing can also help reduce fertiliser runoff, which can lead to environmental pollution and waste.

Using fertiliser tubes can also save time and labour compared to other methods of fertiliser application. They eliminate the need for a separate fertiliser application pass, reducing the overall time and expense of soil preparation.

Sweeps are curved blades that can be attached to plough shanks to help loosen and aerate the soil, control weeds, and incorporate organic matter into the soil. They increase the the shanks effect on the ground, widening the volume of soil lifted and fractured during ploughing. This allows for greater topsoil mixing without disturbing the soil surface layer.

Sweeps can be used for primary tillage, such as deep ripping, to break up compacted soil or to prepare the soil for planting. They can also be used for secondary tillage, to cultivate between rows and control weed growth.

Agrowplow's sweeps for the #9 Shank Assembly come in 200mm or 300mm wide varieties and can fit to any shank with 22mm 1/2" holes.

By loosening and aerating the soil, sweeps can help improve water and nutrient penetration, leading to better crop growth and yields. They can also help incorporate organic matter into the soil, which can increase soil fertility and promote healthy soil structure.

Sweeps can be useful for weed control, as they can uproot and bury weeds, preventing them from reseeding and reducing weed populations in subsequent crops. This can help reduce the need for herbicides and promote more sustainable farming practices.

Not all ploughs can be fitted with sweeps on their front row. Shank recoil, clearance to frame and clearance to any trailing equipment should be checked before purchasing. Sweeps also impact shank recoil action and add approximately 10-15hp to the drawbar requirement for each shank.

Whilst strictly not a shank ‘option’, as they are generally provided as a full shank assembly, inversion shanks are included in this list as they can be useful to achieve specific soil outcomes.

Inversion shanks and options are available for the #9 Shank Assembly and the HD Rigid Assembly.

Inversion shanks are used to completely invert the soil profile, turning over the top layer of soil and burying any surface organic matter or crop residues deep into the subsurface. They are designed to lift soil from the bottom of the working depth up toward the surface. It disrupts soil layering and intermixes the soil while still fracturing and aerating the soil structure.

Using inversion shanks during deep ripping can be useful in situations where soil compaction or surface layer soil problems exist, as they can help to improve soil structure and aeration. It can also be used to bury weed seeds, reducing weed populations in subsequent crops.

Inversion shanks are particularly useful for incorporating large amounts of organic matter or cover crops into the soil. By burying this organic matter, the nutrients it contains are gradually released into the soil over time, improving soil fertility and reducing the need for synthetic fertilisers.

However, it should be noted that inversion ploughing can also have some drawbacks. It can lead to increased soil erosion, and if done too frequently, it can negatively impact soil health by disrupting the natural soil ecosystem. Therefore, inversion ploughing should be used judiciously, and its benefits and drawbacks should be carefully considered before use.

Coulters are mounted in front of the shank assembly and can be installed on any size plough with any of the below attachments, however they are generally recommended for smaller working-width ploughs only.

Most shank options are mutually exclusive, however some cannot be used except under specific circumstances. Shank options often increase draft requirements. Agrowplow recommends speaking to an authorised dealer before considering these options.

TABLE OF SHANK OPTIONS COMPATIBILITY - AGROWPLOW

|